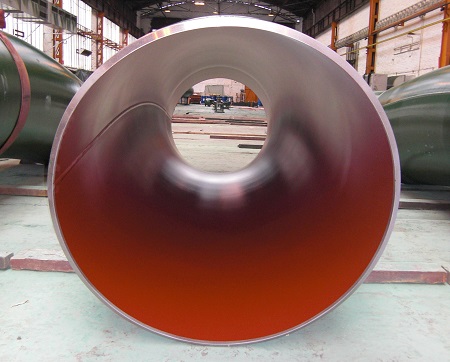

Coating & lining

Depending on the intended application and customer requirements, our pipe bends can be supplied coated / lined or provided with a special surface treatment. This is usually done right at our plant, so no additional transport to a coating plant is required. Surface treatment is always carried out manually.

The following surface treatments are available:*